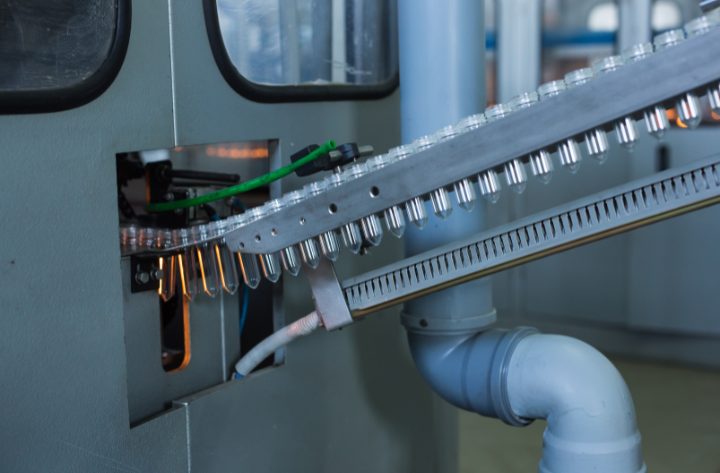

Deflash Equipment for Thermoset Casting

Efficient, Damage-Free Flash Removal for High-Precision Parts

In the thermoset casting industry, surface finish and dimensional accuracy are non-negotiable. Thermoset components—used in automotive, aerospace, medical, and electronics applications—often come out of the mold with hard, brittle flash that must be removed with care. Our plastic deflashing equipment is specifically engineered to meet this challenge, delivering fast, consistent, and gentle finishing for a wide range of molded thermoset parts.

Flash Removal Without Part Damage

Thermoset materials are tough and heat-resistant—but also brittle, making them vulnerable to damage during post-processing. Our plastic media deflashing machines remove excess mold flash efficiently, even on thin or complex features, without distorting or scratching the part.

Perfect for: Electrical insulators, aerospace components, and automotive connectors.

Enhanced Surface Finish for Tight Tolerances

Unlike cryogenic or manual trimming, our process uses soft, non-abrasive plastic media—so there’s no heat, warping, or microcracks. The result? Perfect part integrity, even on delicate geometries.

Safe for use on: Fragile electrical casings, tight-tolerance connectors, and small molded parts.

Labor Savings & High-Volume Throughput

Manual trimming slows production and drives up costs. With our automated plastic deflashing systems, you can eliminate manual inconsistencies, reduce rework, and increase throughput—while maintaining high part quality.

Great for: Job shops and OEMs needing scalable, repeatable finishing.

Compliance with Industry Standards

Our equipment helps manufacturers meet strict quality and safety standards in automotive, aerospace, and medical industries. You can count on flash-free, accurate parts that align with ISO, AS9100, and medical-grade compliance.

Who Uses Our Plastic Deflashing Equipment?

Our systems are trusted by thermoset manufactures across key markets:

- Automotive: Brake pads, ignition components, engine bay connectors

- Aerospace & Defense: Composite housings, structural insulators

- Medical Devices: Surgical tools, prosthetic parts, diagnostic equipment

- Electronics: Switchgear, molded circuit breakers, electrical insulators

Why Thermoset Manufacturers Choose Us?

- Reduce costs: Lower labor and rework expenses

- Ensure consistency: Automated, repeatable surface finishing

- Go eco-friendly: Safer and cleaner than cryogenic methods

- See the results: Sample processing available for proof of performance

Get a Competitive Edge in Thermoset Finishing

If you’re looking to improve quality, speed, and compliance in post-mold processing, our plastic deflasing equipment is the solution.