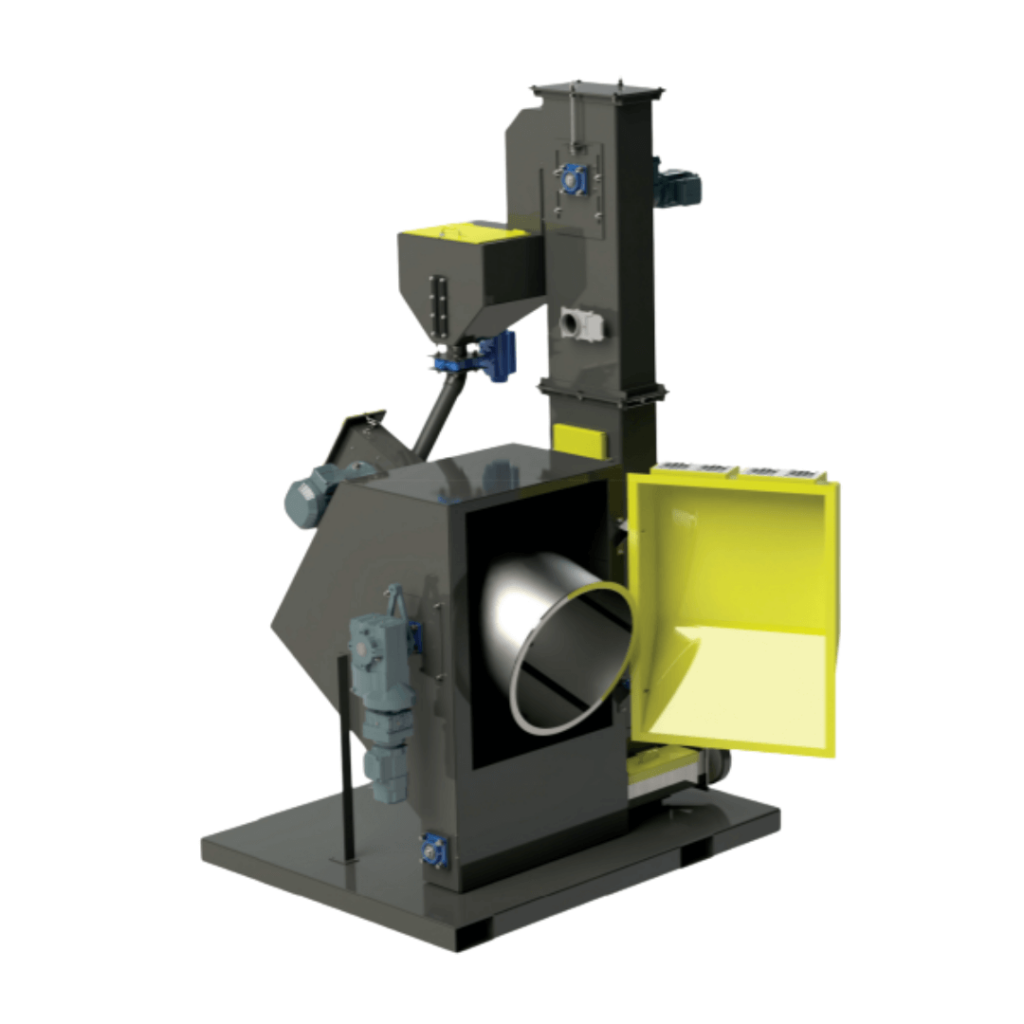

Tumble Drum Deflashing Machine

Our model DEF-DB-2.5 is an automated machine for deflashing batch loads of thermoset plastic parts. Part damage from part-on-part contact or machine pinch points is eliminated within the unique drum design providing a cost-effective solution for deflashing multiple small parts. The unit has a single wheel capable of delivering a wide variety of plastic medias. Parts are gently tumbled in a variable speed rotating drum under the blast stream. Cycle times as well as media delivery speed are also variable to suit the deflashing task needed.

The machine has a complete blast media recycling system with airwash separator to remove debris from the blast media. An anti-static liquid injection system is provided to control static on the media and dust on the parts.

The machine can be automated with loading and unloading equipment to suit many special processing needs. This type of technology is part of a broader range of deflash equipment that are designed to meet various production needs.

TYPICAL APPLICATIONS OF THE TUMBLE DRUM DEFLASHING MACHINE

- All types of thermoset molded parts

- Small parts that cannot be deflashed using belt conveyor type machines

- Fragile switch components and handles for circuit breakers

- Electrical circuit components

- Terminal housings

FEATURES AND BENEFITS OF TUMBLE DRUM DEFLASHING MACHINE

- Single blast wheel with aluminum impeller and stainless steel liners

- Fully welded steel dust tight cabinet with large work door to facilitate easy access to the drum and machine internals

- Seamless tumbling drum with no pinch-points and ¼” drain holes or custom hole to meet your application

- 2.5 cubic foot capacity

- Easily assessable screens for capturing large debris

- Variable speed controls of the wheel and drum along with variable cycle time allow for precise process control

- Anti-static system with large reservoir and vari-flow pump

- Compact design with base plate for easily moving around the facility

AVAILABLE OPTIONS

- Automatic loaders and unloaders

- Customized control systems and components

- Stainless steel components

- Dust collector

- Door opening and/or the drum tilt can be powered to suit automation or ease for operating

TUMBLE DRUM DEFLASHING MACHINE SPECIFICATIONS

Model

DEF-DB-2.5

Machine Dimensions

120” tall x 72” wide x 60” deep

Load Height

40” from floor level

Unload Height

25” from floor level

Tumble Drum

24” diameter x 24” deep

Work Piece

Minimum ½” Maximum 6”